CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by automating complex machining tasks with unparalleled precision. Over the years, these machines have evolved, incorporating more axes to perform intricate movements and achieve higher accuracy. But what exactly is the highest-axis CNC machine available, and does exceeding the well-known 5-axis model significantly enhance performance? In this article, we explore the concept of multi-axis CNC machines, from their benefits to their limitations, and discover if more axes truly mean more precision.

What is the Highest Axis CNC Machine (12 axis)?

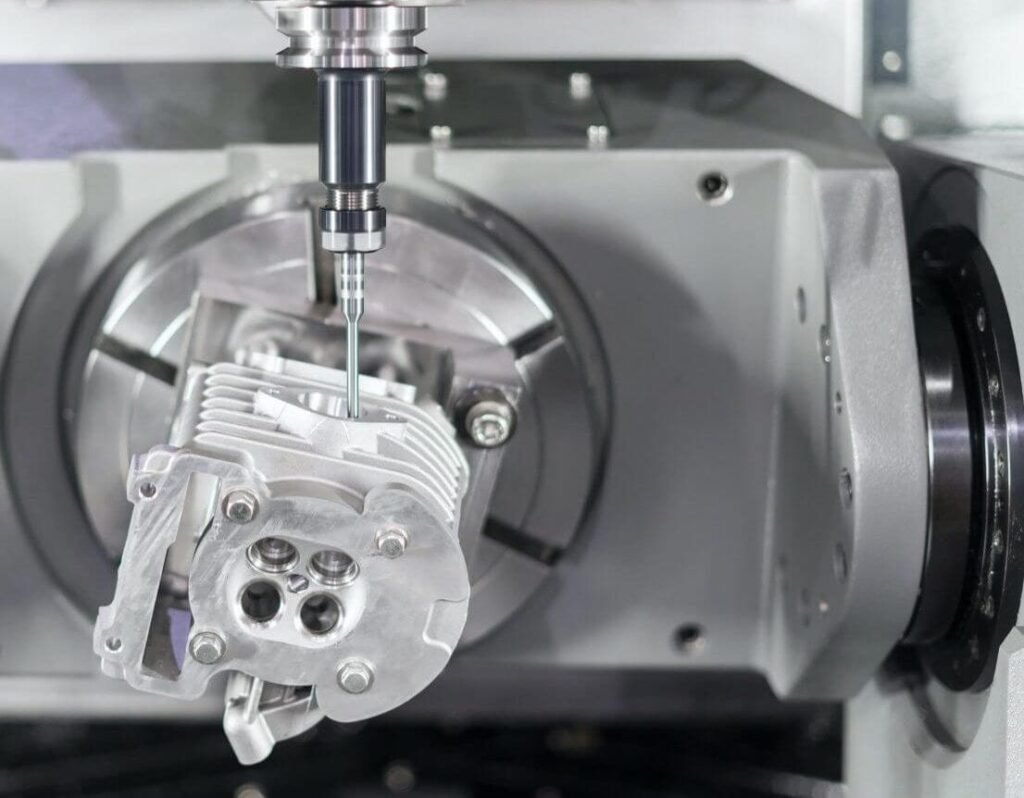

The highest-axis CNC machine currently available is the 12-axis CNC machine. These advanced machines are designed to handle ultra-complex tasks with precision and flexibility far beyond what standard models can offer. A 12-axis CNC machine provides enhanced control over rotational and linear movements, allowing manufacturers to produce components with intricate features and detailed contours. Each additional axis provides a new level of movement, ensuring that every angle and surface of a part can be machined without the need for manual repositioning.

How Do Axes Work in CNC Machines?

In precision CNC machining, axes refer to the direction the cutting tool or the workpiece can move. A standard CNC machine operates on three axes—X, Y, and Z. These correspond to the three-dimensional planes of movement: side-to-side (X), forward and backwards (Y), and up and down (Z). As more axes are added, rotational movement comes into play, increasing the machine’s ability to maneuver and cut from multiple angles simultaneously. This multi-axis capability is essential for creating parts with complex geometries, such as turbine blades or medical implants.

5-Axis CNC Machines: The Industry Standard

While 12-axis CNC machines exist, the industry standard for most high-precision tasks remains the 5-axis CNC machine. These machines add two rotational axes to the standard three, giving the cutting tool more flexibility to approach the workpiece from virtually any angle. This reduces the need for multiple setups, increases efficiency, and improves the quality of the finished product. The 5-axis machine balances precision, complexity, and cost-effectiveness for most industries, including aerospace, automotive, and medical manufacturing.

Advantages of 5-Axis CNC Machines

- Fewer setups: The ability to rotate both the tool and the workpiece allows for machining multiple sides of a part in a single setup, saving time and reducing errors.

- Improved surface finish: The tool’s ability to move in complex patterns results in smoother finishes, especially on contoured surfaces.

- Greater flexibility: Complex geometries can be easily produced, allowing manufacturers to design more intricate parts.

More Axes, More Precision? (Exceeding 5 Axis is Meaningless for Most Applications)

While 12-axis CNC machines offer impressive capabilities, there’s a strong argument that exceeding 5 axes is unnecessary for most applications. More axes don’t always translate into more precision. A 5-axis CNC machine provides more than enough flexibility and control for most manufacturing tasks. The complexity of controlling additional axes can also lead to diminishing returns as the benefits become less noticeable in standard machining processes. For this reason, 5-axis machines are considered the optimal choice for industries requiring both precision and efficiency.

When is a 12-axis CNC Machine Necessary?

Despite the limitations of more than five axes, 12-axis CNC machines are indispensable for specific high-tech applications. These machines are typically used in industries that require complex parts with intricate internal features that can’t be achieved through other methods. Examples include:

- Aerospace: Manufacturing turbine blades or other aerodynamic components with extreme precision.

- Medical devices: Creating implants or surgical tools that require flawless finishes and exacting tolerances.

- High-performance engineering: Producing parts that must maintain performance under extreme conditions, such as in motorsports or space exploration.

In these cases, the extra axes allow for greater control over the part’s geometry, ensuring that even the most demanding designs can be manufactured to exact specifications.

Limitations of Multi-Axis CNC Machines

Though the additional axes provide more movement and control, multi-axis CNC machines have several drawbacks. For starters, the cost of a 12-axis CNC machine can be prohibitively expensive, often limiting its use to niche industries. The increased complexity also means more difficult programming, higher maintenance costs, and longer setup times. Operators require specialized training to understand and utilize all of the axes fully, and even with this, the benefits of using more than five axes may be negligible for simpler tasks.

Increased Setup Times

With each additional axis, the machine setup becomes more complex. More axes mean more factors to control, making it harder to program the machine quickly and efficiently. This can result in longer lead times and increased labor costs, especially in smaller production runs where speed is a priority.

Higher Costs

Another consideration is the financial investment required for multi-axis machines. Not only are 12-axis machines more expensive to purchase, but they also require ongoing maintenance and specialized parts. This makes them a costly option for businesses that don’t need such advanced capabilities regularly.

Conclusion

While the 12-axis CNC machine is the pinnacle of modern machining technology, it is not necessarily the best option for all applications. For most manufacturers, the 5-axis CNC machine provides precision, efficiency, and cost-effectiveness. Exceeding five axes can result in diminishing returns, especially when the added complexity and cost are factored in.

However, in certain specialized industries, where ultra-precise parts with complex geometries are required, machines with more than five axes, such as the 12-axis CNC machine, offer unmatched capabilities. Ultimately, the right choice of machine depends on the specific demands of the task, with more axes being valuable only in niche scenarios.